Secondary Completion – Water/ CO2 Gasflood

In primary natural resource reco very, the initial approach to produce oil is generally via natural reservoir pressure or simple mechanical pumps used to raise oil to the surface. Most oil wells today have to be pumped. Primary oil recovery can only produce a small fraction of the oil in a reservoir. The need for secondary oil recovery methods arise from this fact. Waterflooding can be both effective and economical.

very, the initial approach to produce oil is generally via natural reservoir pressure or simple mechanical pumps used to raise oil to the surface. Most oil wells today have to be pumped. Primary oil recovery can only produce a small fraction of the oil in a reservoir. The need for secondary oil recovery methods arise from this fact. Waterflooding can be both effective and economical.

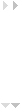

Secondary recovery of remaining oil from a proven reservoir can be obtained by injecting water/gas (‘water/CO2 gasflooding)’, to maintain reservoir pressure and push oil out of the rock. Prolonged oil production can be achieved effectively once the primary production has tapered off. This is called secondary recovery

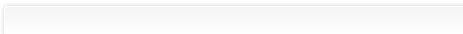

A well planned oil field can go a long way toward the reliability and overall cost effectiveness of a water/CO2 gasflooding project. One method uses centrally located wells that, once primary and secondary production declines, will be used as injection wells.

These injection wells use water/CO2 gas to forc e the remaining oil reserves toward the extremities of the oil field. Increasing the viscosity of the water, allowing for drillers to gain ‘control’ over where the water flows. This allows for the introduction of water/CO2 gas into areas of the reservoir in which it naturally wouldn’t flow. By forcing water/CO2 gas into the crevices around an oil reserve, oil can be ‘moved’ toward the production zone. Such techniques can raise production on these outer wells to near initial production numbers as well as allow for the recovery of up to 80% of the remaining reserves.

e the remaining oil reserves toward the extremities of the oil field. Increasing the viscosity of the water, allowing for drillers to gain ‘control’ over where the water flows. This allows for the introduction of water/CO2 gas into areas of the reservoir in which it naturally wouldn’t flow. By forcing water/CO2 gas into the crevices around an oil reserve, oil can be ‘moved’ toward the production zone. Such techniques can raise production on these outer wells to near initial production numbers as well as allow for the recovery of up to 80% of the remaining reserves.

Oil reservoirs suitable for secondary recovery projects have produced for several years. It takes time to inject sufficient water/CO2 gas to fill enough of the void spaces to begin to move the oil.